-

Phone

86-532-85029512

-

Address

Room 12b10, B Block, Wanke Center, No. 2 of Heilongjiang South Road Shibei, Qingdao, Shandong, China

-

E-mail

LatestProducts

Hot Sale Precision Aluminum Die Casting Part and Mold

China Hot Sale Precision Aluminum Die Casting Part and Mold, Find details about China Water Glass Casting Impeller, Impeller from Hot Sale Precision Aluminum Die Casting Part and Mold - A&T Industry Co., Ltd.

Description

Basic Info

- Model NO.: casting part

- Casting Form Material: Metal

- Casting Form Usage Count: Permanent

- Surface Roughness: Ra0.2

- Machining Tolerance: +/-0.15mm

- Certification: SGS, CE, RoHS, ISO 9001:2000

- Surface Condition: Sand Blasting

- Trade Mark: at OEM ODM

- Shipping Port: Qingdao

- Transport Package: Wooden Box

- Origin: China

- Casting Method: Sand Casting

- Casting Metal: Nonferrous Alloys

- Surface Treatment: Polishing

- Coating: Water

- Standard: AISI

- Package: Within Wooden Crate

- Original: China

- Production Capability: 30,000 PCS / Month

- Trademark: AT

- Specification: CE SGS ISO

- HS Code: 84485900

Product Description

A&T Industry is a contract manufacture and exporter of high quality forging parts,casting part,machining part,stamping part with more than 13 years experience.

Quick Details

Packaging & Delivery

Manufacturing Process of Nantong JianXiang Casting:

Investment Casting or Lost-wax Casting, focus on materials of Carbon Steel, Stainless Steel.

Sand Casting, Focus on materials of Iron, Steel and Aluminum.

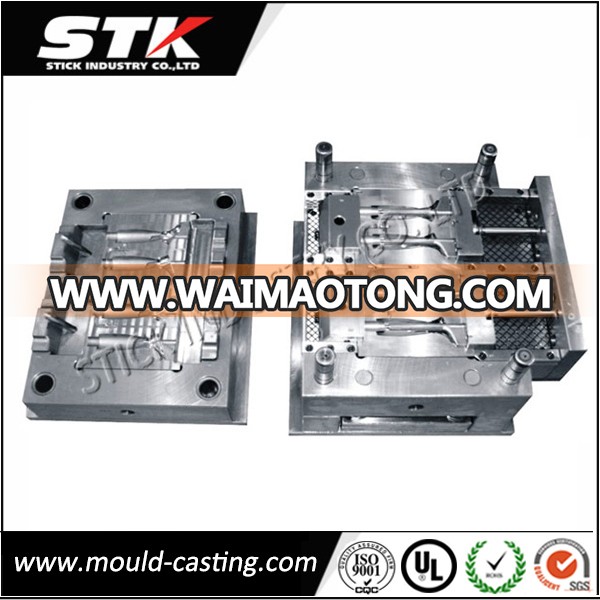

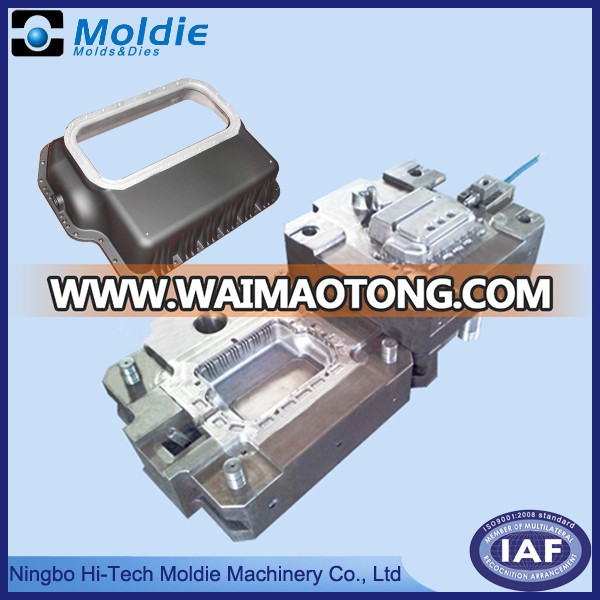

Die Casting, Aluminum Alloy, Zinc Alloy.

CNC Machining,Turning,Milling,Drilling and Grinding on the castings

Quality Certification:

We are ISO9001:2008 Certified, we offer below testing and report:

Spectral Analysis, Full Dimension Report, Material Certification, Mechanical Performance Testing, Hydro Testing, Ultrasonic inspection could be provided on our casting parts.

Our Main Products:

Stainless Steel Casting, Carbon Steel Casting, Alloy Steel Casting, Aluminum Casting, Bronze Casting, Iron Casting ,Impellers, Bearing Seat/Cap, Valve Body, Valve Housing, Pump Housing, Pump Case, Valve Balls, Turning Shaft, Manifold, End Covers, Washers, Pump Parts, Automobile castings, Stainless steel marine hardware casting parts, architecture hardware, Copper alloy castings, Mining & Earthmoving machinery accessories, Ships & Train & Automobile & Motorcycle fittings, Electric machine & hardware fittings etc.

What Surface Treatment can we offer:

Zinc plating/Galvanized, Chrome plating, Polishing, Painting, Powder coating, Shot blasting,

Sand blasting, Phosphating, Grinding, Electrophoresis, Anodizing, Black Oxide etc.

Material Standard we can Follow and produce:

GB. ASTM. AISI. DIN. BS. JIS. NF. AS. AAR

Investment Casting: 201, 202, 303, 304, 304L, 316, 316L, 1Cr18Ni9Ti, 430, 440, 1008, 1020, 20NiCrMo, 30CrMo, 42CrMo4

Sand Casting: Ductile Iron, Gray Iron, Aluminum, Steel etc.

Die Casting: ADC12, A380, A356, ZAMAK 3, ZAMAK5 etc.

Manufacturing Limitations:

Max linear Size:2200mm; Max Diameter Size:1000 mm

Casting Weight range: 0.02~2000Kg

Best Casting Surface Roughness: Ra 3.2um~12.5um(by Investment Casting and Die Casting)

Quick Details

|

Place of Origin: |

Shandong China (Mainland) |

Brand Name: |

AT |

Model Number: |

A&T investment casting |

|

Application: |

Carbon Steel Pipe Fittings |

Material: |

Steel |

Dimensions: |

Water Glass Castings |

|

Casting: |

stainless steel |

Packaging & Delivery

|

Packaging Details: |

Standard Exporting Packaging |

| Delivery Detail: | 30 Days |

Manufacturing Process of Nantong JianXiang Casting:

Investment Casting or Lost-wax Casting, focus on materials of Carbon Steel, Stainless Steel.

Sand Casting, Focus on materials of Iron, Steel and Aluminum.

Die Casting, Aluminum Alloy, Zinc Alloy.

CNC Machining,Turning,Milling,Drilling and Grinding on the castings

Quality Certification:

We are ISO9001:2008 Certified, we offer below testing and report:

Spectral Analysis, Full Dimension Report, Material Certification, Mechanical Performance Testing, Hydro Testing, Ultrasonic inspection could be provided on our casting parts.

Our Main Products:

Stainless Steel Casting, Carbon Steel Casting, Alloy Steel Casting, Aluminum Casting, Bronze Casting, Iron Casting ,Impellers, Bearing Seat/Cap, Valve Body, Valve Housing, Pump Housing, Pump Case, Valve Balls, Turning Shaft, Manifold, End Covers, Washers, Pump Parts, Automobile castings, Stainless steel marine hardware casting parts, architecture hardware, Copper alloy castings, Mining & Earthmoving machinery accessories, Ships & Train & Automobile & Motorcycle fittings, Electric machine & hardware fittings etc.

What Surface Treatment can we offer:

Zinc plating/Galvanized, Chrome plating, Polishing, Painting, Powder coating, Shot blasting,

Sand blasting, Phosphating, Grinding, Electrophoresis, Anodizing, Black Oxide etc.

Material Standard we can Follow and produce:

GB. ASTM. AISI. DIN. BS. JIS. NF. AS. AAR

Investment Casting: 201, 202, 303, 304, 304L, 316, 316L, 1Cr18Ni9Ti, 430, 440, 1008, 1020, 20NiCrMo, 30CrMo, 42CrMo4

Sand Casting: Ductile Iron, Gray Iron, Aluminum, Steel etc.

Die Casting: ADC12, A380, A356, ZAMAK 3, ZAMAK5 etc.

Manufacturing Limitations:

Max linear Size:2200mm; Max Diameter Size:1000 mm

Casting Weight range: 0.02~2000Kg

Best Casting Surface Roughness: Ra 3.2um~12.5um(by Investment Casting and Die Casting)